Let’s learn about the plastic for cosmetic packaging

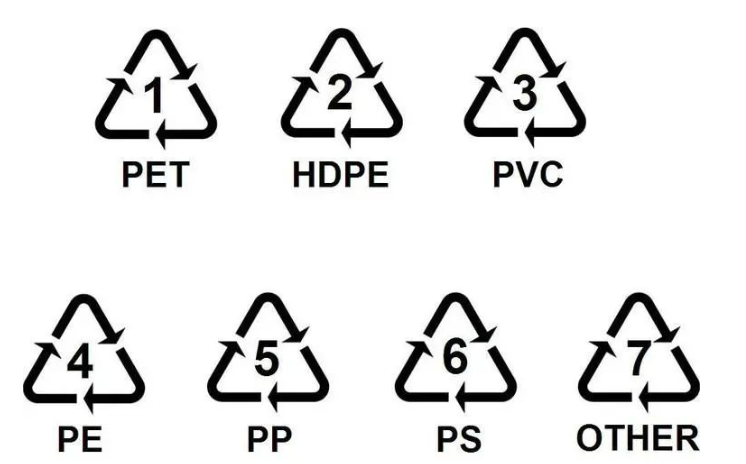

Plastic bottles are mainly made of polyethylene or polypropylene and other materials and add a variety of organic solvents. Plastic bottles widely use polyester (PET), polyethylene (PE), and polypropylene (PP) as raw materials, adding the appropriate organic solvents, after high-temperature heating, through the plastic mold through the plastic blow molding, extrusion blowing, or injection molding plastic containers.

PET、PE、PP、ABS、AS、Acrylic

PET: environmentally friendly material can be directly in contact with the material body, Advantages: high barrier properties, lightweight, not broken, high transparency, softer material. Disadvantages: not resistant to high temperature, easy to change shape above 40 degrees.

PE: environmentally friendly materials can be directly in contact with the material body, a molding, direct injection of finished products, matte surface, not as bright as PET, the caliber of the rougher, can not do the effect of transparency, the surface treatment of PE material is not suitable for spraying, can not be colored, easy to fall, silk screen printing need to be a special overfire treatment.

PP: environmentally friendly materials can be directly in contact with the material body, low density, strength, stiffness, hardness, and heat resistance are better than PET.

It can be used at about 100 degrees, but the low temperature makes it brittle not wear-resistant, so generally used for cosmetic lids preferred material.

Normally, ABS, AS, and PS are popular in the market for eyeshadow palettes, lipstick/lip gloss tubes and foundation, and highlight stick cases.

ABS: good strength, good toughness, easy to process molding thermoplastic polymer materials, its high strength, corrosion resistance, high-temperature resistance, so often used in the shell of the product, the surface of the processed product is smooth and clean, easy to dye and plating, some of the need to do plating of the lid are generally selected from this material. Some double-layer skincare and beauty bottles are also commonly used for this material.

AS, ABS: AS transparency is better than ABS, and better toughness.

Acrylic: material for injection molded bottles, chemical resistance is poor, generally can not be directly loaded with cream, needs to match the liner barrier, filling is not easy to be too full, to prevent the cream into the liner and acrylic bottles, avoid cracking, the transportation of the packaging requirements of the higher, due to the scratches look particularly obvious after the translucency of the high perception of the wall of the extra-thick, but the price is quite expensive.

If you want to learn more, please contact us.

Email: [email protected] WhatsApp&WeCat: +8613538682605